Table of Contents

ToggleIn the world of 3D printing, ASA is like that reliable friend who always shows up on time—except this friend can withstand the elements and look good doing it. With its impressive durability and UV resistance, ASA is quickly becoming the go-to material for outdoor applications and functional prototypes. If you’ve ever dreamed of creating parts that can brave the harshest weather without fading or warping, ASA might just be your new best buddy.

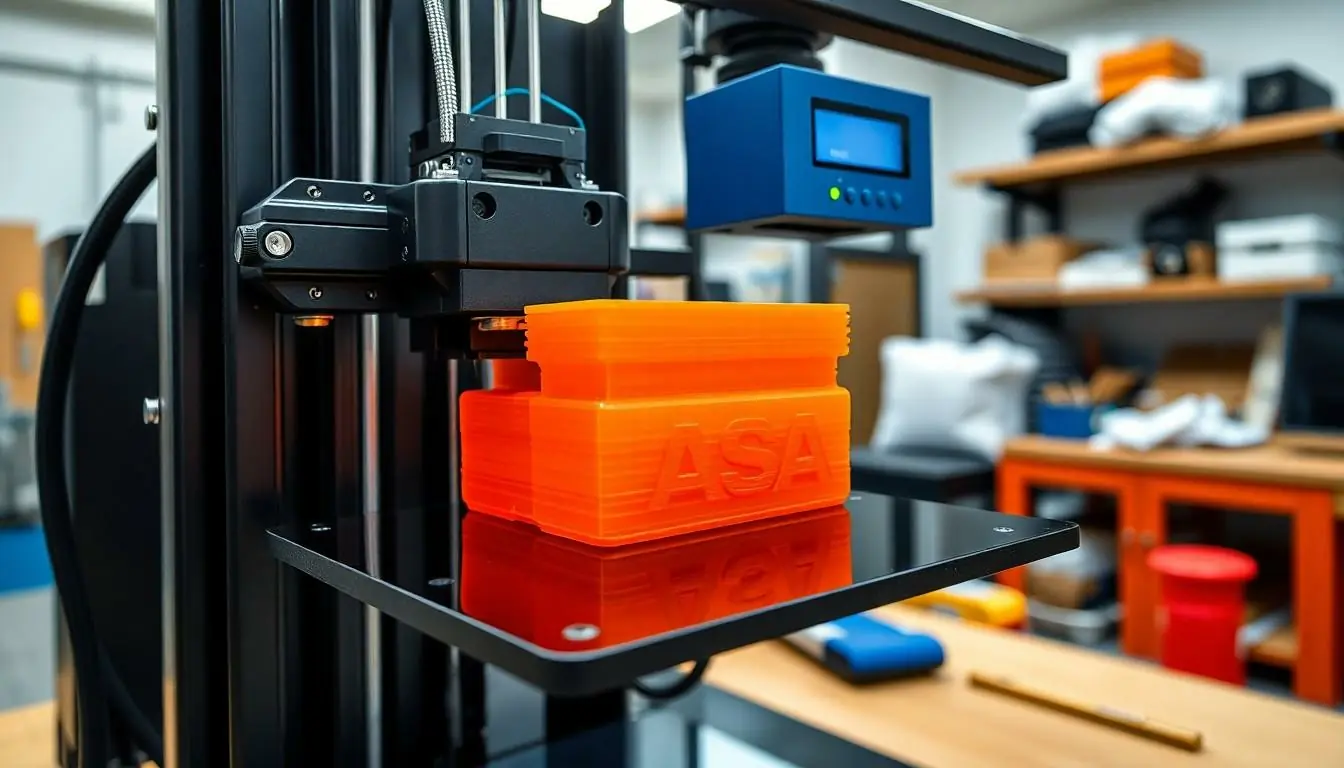

Overview of ASA 3D Printing

ASA, or Acrylonitrile Styrene Acrylate, stands out as a versatile filament in the 3D printing landscape. Known for its exceptional durability, ASA excels in applications requiring resilience against environmental stressors. High UV resistance allows printed parts to maintain their appearance and strength when exposed to sunlight, making ASA ideal for outdoor projects.

Many designers rely on ASA for functional prototypes due to its ability to mimic the properties of ABS while offering improved performance. Printing with ASA yields parts that resist warping during the cooling process, which ensures precision in dimensions and reduces the need for post-processing.

Temperature stability is another key feature of ASA. Its thermal resistance supports the creation of items that can endure fluctuations in heat without deforming. Users often appreciate this quality in more demanding environments.

Cost-effective and readily available, ASA presents an attractive option for both hobbyists and professionals. It adheres well to a variety of surfaces, simplifying the printing process and enhancing layer bonding. Additionally, layers bond effectively, resulting in strong, durable finished products.

ASA’s unique combination of durability, UV resistance, and thermal stability positions it as a go-to filament for projects where reliability matters. Whether for outdoor signage, automotive parts, or industrial applications, ASA provides a robust solution, ensuring that printed items hold their integrity over time.

Benefits of ASA 3D Printing

ASA (Acrylonitrile Styrene Acrylate) offers multiple benefits that make it a preferred choice in 3D printing, especially for demanding applications.

Durability and Strength

Durability defines ASA, making it a robust option for various projects. The material exhibits high impact resistance, ensuring parts endure rigorous use without compromising structural integrity. ASA maintains its shape under stress, reducing the likelihood of breakage. This strength also extends to its layering process, allowing for superior adhesion between layers. Parts made from ASA withstand mechanical forces, presenting a reliable choice for functional prototypes and end-use components. Overall, the strong performance of ASA fosters confidence in its use across multiple applications.

UV Resistance

UV resistance significantly enhances ASA’s appeal for outdoor applications. This filament resists fading and degradation when exposed to sunlight, ensuring products retain their vibrant appearance over time. Outdoor signage and automotive parts benefit from this feature, as both must withstand harsh sunlight without losing quality. Additionally, ASA’s performance under UV exposure translates to lower maintenance costs. Manufacturers and designers favor ASA for projects requiring long-lasting visual integrity. Overall, its UV resistance contributes to extended durability and functionality.

Thermal Stability

Thermal stability makes ASA an excellent choice in environments subject to temperature fluctuations. The material withstands heat without deforming, which is crucial for parts exposed to varying conditions. This characteristic ensures that ASA retains its shape and dimensions even under demanding circumstances. End-use applications such as automotive components and outdoor fixtures thrive with ASA due to its capacity to endure heat. ASA’s ability to maintain performance through temperature extremes enhances its reliability for projects that account for thermal stresses. Overall, thermal stability solidifies ASA’s reputation in diverse markets, particularly where temperature control is vital.

Applications of ASA 3D Printing

ASA 3D printing finds diverse applications across multiple industries due to its exceptional properties. This versatility allows for effective utilization in various sectors.

Industrial Uses

Industrial sectors widely utilize ASA for components exposed to harsh environments. Manufacturing machines, equipment housings, and outdoor fixtures benefit from the material’s durability and UV resistance. Assembly line parts crafted with ASA exhibit high impact resistance, ensuring longevity even under strenuous conditions. Factories and warehouses prefer ASA for its cost-effectiveness and reliability, crucial for maintaining operational efficiency. Furthermore, industries favor ASA for its ability to adhere well to different surfaces, enhancing component performance and robustness.

Prototyping

Prototyping processes greatly benefit from ASA’s strength and thermal stability. Designers and engineers rely on this material for creating functional prototypes that withstand testing conditions without warping or deforming. Its superior layer adhesion results in prototypes that closely mimic final products, which aids in precise validation. Teams appreciate ASA for reducing post-processing time because of its excellent printability. Rapid development cycles become possible with ASA, allowing for faster iterations and improved product design.

End-Use Parts

End-use parts manufactured with ASA excel in applications requiring durability and resilience. Outdoor signage displays, automotive components, and custom fixtures frequently utilize this material for its long-lasting performance. Parts designed to face environmental challenges maintain structural integrity and visual appeal, thanks to ASA’s UV resistance and thermal stability. Manufacturers find value in producing high-quality end-use components that endure everyday wear while minimizing maintenance needs. This reliability in demanding applications has solidified ASA’s role as a preferred choice in parts production.

Comparison with Other Filaments

ASA stands out in the 3D printing world, offering unique advantages over other filaments like ABS and PLA. This comparison highlights its strengths and applications.

ASA vs. ABS

ASA and ABS share similar thermal properties and ease of printing, making them both popular choices. ASA surpasses ABS with superior UV resistance, ensuring outdoor applications last longer without fading. Unlike ABS, ASA resists warping during cooling, enhancing precision and reducing post-processing needs. The impact resistance of ASA matches that of ABS, but ASA maintains structural integrity even in challenging environments. For projects requiring durability and performance under sunlight, ASA proves to be a more reliable option than ABS.

ASA vs. PLA

Contrasting with PLA, ASA offers enhanced durability and heat resistance. PLA provides ease of printing, but its brittleness limits practical applications in demanding environments. ASA excels in outdoor settings where UV stability and structural strength are vital. This filament handles temperature variations without deforming, making it suitable for automotive and industrial components. While PLA is biodegradable, ASA’s longevity in harsh conditions makes it preferable for long-lasting, functional parts. In scenarios where durability and exposure to the elements matter, ASA clearly outshines PLA.

ASA 3D printing stands out as a versatile and reliable choice for various applications. Its exceptional durability and UV resistance make it a top contender for outdoor projects where longevity is crucial. With its ability to withstand harsh conditions and maintain structural integrity, ASA proves to be a practical solution for both prototyping and end-use parts.

The material’s thermal stability further enhances its appeal in demanding environments. As industries continue to seek durable and cost-effective materials, ASA’s unique properties position it as a preferred filament for professionals looking to achieve high-quality results. Embracing ASA in 3D printing can lead to innovative solutions that meet the challenges of modern design and manufacturing.