Table of Contents

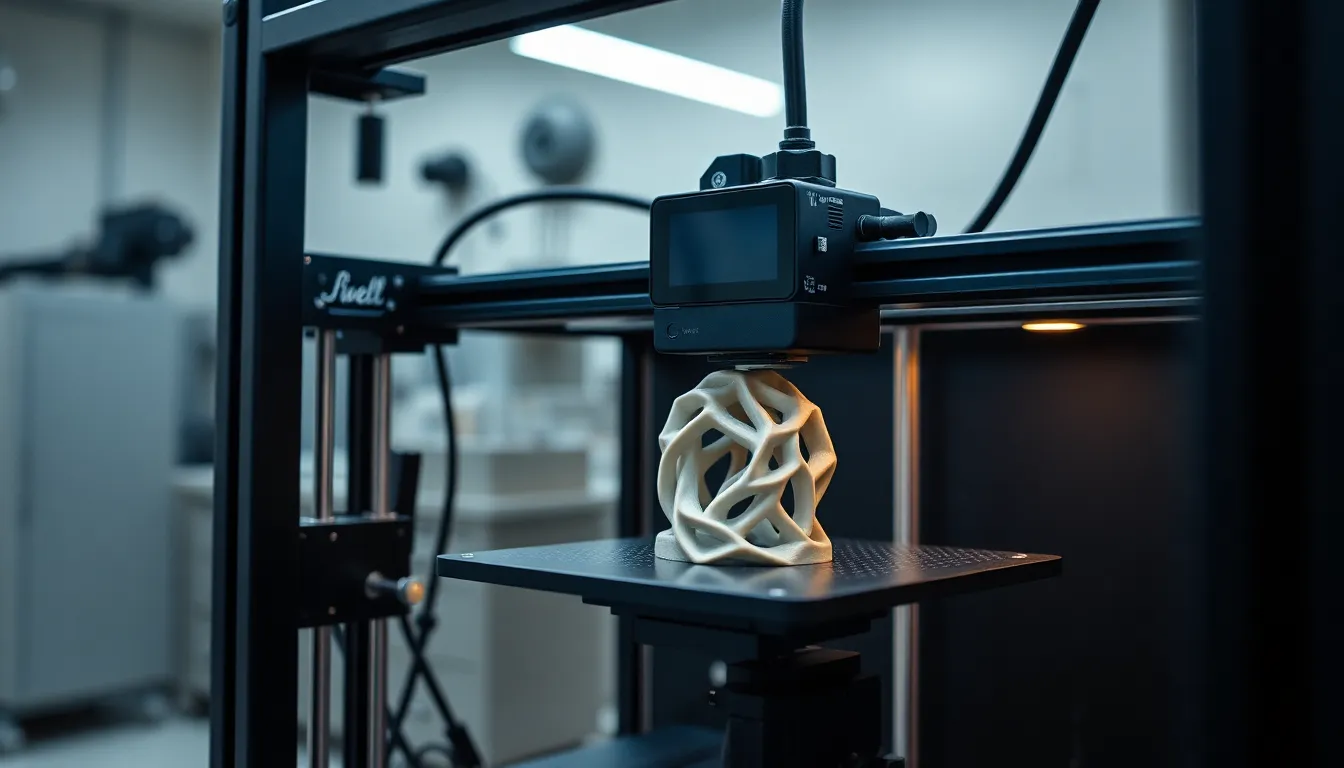

ToggleThe 3D printing market is like a magician’s hat—full of surprises and endless possibilities. What once seemed like science fiction is now a booming industry, transforming everything from manufacturing to healthcare. Imagine printing your own custom sneakers or even a new organ for transplant. Sounds wild, right? Well, it’s happening, and it’s reshaping how businesses operate.

As the technology evolves, the market’s growth is skyrocketing faster than a 3D printer can spit out a plastic dinosaur. With innovations popping up daily, companies are rushing to harness this game-changing tool. Whether you’re a DIY enthusiast or a corporate giant, the 3D printing revolution is here to stay, and it’s time to jump on board before you get left in the dust—or worse, stuck with a boring old assembly line.

Overview of the 3D Printing Market

The 3D printing market experiences significant growth, with a projected CAGR of 21% from 2023 to 2030. Industries such as aerospace, automotive, and healthcare leverage this technology to create prototypes and finished products more efficiently. A diverse range of materials, including plastics, metals, and ceramics, is used in the 3D printing process, allowing for the production of complex geometries that traditional methods cannot achieve.

Healthcare showcases notable innovations thanks to 3D printing. Dental implants, custom prosthetics, and even bioprinted tissues represent just a few applications revolutionizing patient care. Manufacturers benefit from reduced material waste and shorter lead times, enhancing overall production efficiency.

Additionally, advancements in software tools and printing technology contribute to market expansion. Companies now outperform competitors by adopting additive manufacturing processes that streamline operations and enable rapid iteration on product designs. The integration of 3D printing into supply chains further enhances flexibility and responsiveness, making businesses more agile in a fast-paced market.

Regional trends indicate growth in North America and Asia-Pacific, driven by increased investment and supportive government initiatives. Various startups emerge, focusing on niche applications, fostering innovation and attracting investment in this volatile landscape. As established firms adopt 3D printing, entering collaborations with startups accelerates progress, pushing the boundaries of what’s achievable.

The 3D printing market is transforming industries through innovative applications and continuous advancements, positioning itself as an essential part of the modern manufacturing ecosystem.

Key Trends in the 3D Printing Market

3D printing is evolving rapidly, shaped by several key trends that influence its trajectory. Significant advancements continue to emerge, enhancing the technology’s capabilities and applications across various sectors.

Technological Advancements

Innovations in materials are crucial. New composite materials offer improved strength and flexibility, allowing for the production of more durable parts. Enhanced software tools streamline design processes significantly, enabling quicker iterations and greater design complexity. Integration of artificial intelligence in printing technologies maximizes efficiency and precision. Automation in post-processing steps reduces time and labor costs. Each of these advancements contributes to the market’s expansion and increased adoption by manufacturers.

Market Growth Drivers

The 3D printing market experiences robust growth driven by several factors. Demand for rapid prototyping plays a pivotal role, allowing companies to expedite product development cycles. Customization trends in consumer products and medical devices enhance the appeal of additive manufacturing. Increased investments from established firms in new technologies fuel innovation and market entry. Supportive government initiatives in regions like North America and Asia-Pacific foster a conducive environment for startups focusing on niche applications. Each of these drivers reinforces the necessity for industries to adopt 3D printing solutions.

Major Players in the 3D Printing Market

Significant players shape the 3D printing market, driving innovation and competition. Companies like Stratasys, 3D Systems, and Siemens lead in providing robust solutions across various industries.

Company Profiles

Stratasys offers a range of 3D printing technologies, including FDM and PolyJet. They target aerospace, automotive, and healthcare sectors with comprehensive solutions. 3D Systems, a pioneer, specializes in metal and plastic printers. Their portfolio includes services for prototyping, custom production and healthcare applications. Siemens leverages its expertise in automation and software to enhance additive manufacturing. They focus on integrating 3D printing into smart factories. Additional players, such as HP and Formlabs, expand market offerings with innovative materials and reliable printers for small businesses.

Competitive Landscape

The competitive landscape in the 3D printing market showcases a mix of established companies and emerging startups. Key competitors emphasize partnerships and collaborations to foster innovation. For instance, strategic alliances between startups and major corporations enhance capabilities in specific applications. A surge in investments also contributes to competition, as firms seek to capture market share. Notably, large firms focus on developing proprietary technologies to differentiate themselves. Startups frequently address niche markets, promoting unique solutions tailored for specialized needs. As new players enter the market, they challenge incumbents, ensuring ongoing advancements and competition.

Applications of 3D Printing

3D printing serves various industries, showcasing its versatility and transformative potential. Numerous sectors harness this technology for enhanced production efficiencies and innovative solutions.

Industries Utilizing 3D Printing

Aerospace industries leverage 3D printing for lightweight components and complex geometries. Automotive companies utilize this technology to create prototypes and end-use parts quickly. Healthcare sectors benefit from customized medical devices, such as dental implants and prosthetics. The consumer goods sector also experiences enhancements through 3D printed personalized items, matching individual preferences with efficiency. Retailers explore unique product offerings, expanding their market reach through tailored designs.

Innovative Use Cases

Unique applications emerge daily with advancements in 3D printing. Bioprinting, for instance, enables the creation of living tissues and organs for medical research. Educational institutions employ 3D printing to develop educational materials, enhancing student engagement. Artists and designers embrace this technology to produce intricate sculptures and fashion pieces. Construction firms experiment with 3D printed building structures, aiming for quicker and more sustainable construction methods. Food industries explore 3D printed edible items, offering novel culinary experiences.

Future Outlook of the 3D Printing Market

The 3D printing market is on track for substantial growth. Projected to expand at a CAGR of 21% from 2023 to 2030, this sector will likely reshape manufacturing and healthcare industries significantly. Strong demand stems from aerospace and automotive sectors, where companies emphasize efficiency in prototype production and finished goods.

Innovations in materials play a critical role in this transformation. New composite materials enhance product strength and flexibility, attracting interest from manufacturers seeking competitive advantages. Software advancements streamline design processes, enabling faster iterations and reducing time-to-market for new products.

Artificial intelligence integration enhances efficiency across various operations, while automation in post-processing cuts down labor costs. Such innovations invigorate market growth, driven by the push for rapid prototyping and customized solutions in medical devices. Increased investments from established firms bolster the environment for emerging startups focusing on niche applications.

Key players like Stratasys, 3D Systems, and Siemens lead the way in driving competition and innovation. Stratasys targets multiple industries with its broad technology range. Meanwhile, 3D Systems focuses on metal and plastic printers, catering to diverse applications. Siemens brings additive manufacturing to the next level by integrating advanced automation and software solutions.

Today, diverse applications highlight the versatility of 3D printing. The aerospace industry utilizes additive manufacturing for lightweight components and intricate designs. Custom medical devices gain traction in healthcare, while consumer goods benefit from personalized products. Creative use cases also emerge, such as bioprinting living tissues and producing educational materials, demonstrating the expanding impact of this technology across various fields.

The 3D printing market stands at the forefront of innovation and transformation across multiple industries. With a projected CAGR of 21% from 2023 to 2030, its influence is undeniable. Companies adopting this technology are not just enhancing efficiency but are also redefining product possibilities.

As advancements in materials and software continue to emerge, the potential for customized solutions expands. The collaboration between established firms and startups fosters an environment ripe for creativity and competition. Embracing 3D printing is no longer optional; it’s essential for those looking to thrive in a rapidly evolving marketplace. The future of manufacturing is being shaped today, and staying ahead means leveraging the unique advantages that 3D printing offers.