Table of Contents

ToggleIn a world where everything seems to be getting smaller, faster, and more complex, industrial 3D printing is the superhero we didn’t know we needed. Imagine a factory that doesn’t just assemble parts but creates them layer by layer, like a digital magician pulling rabbits out of thin air. This technology isn’t just a fad; it’s revolutionizing how industries design, produce, and innovate.

Overview of Industrial 3D Printing

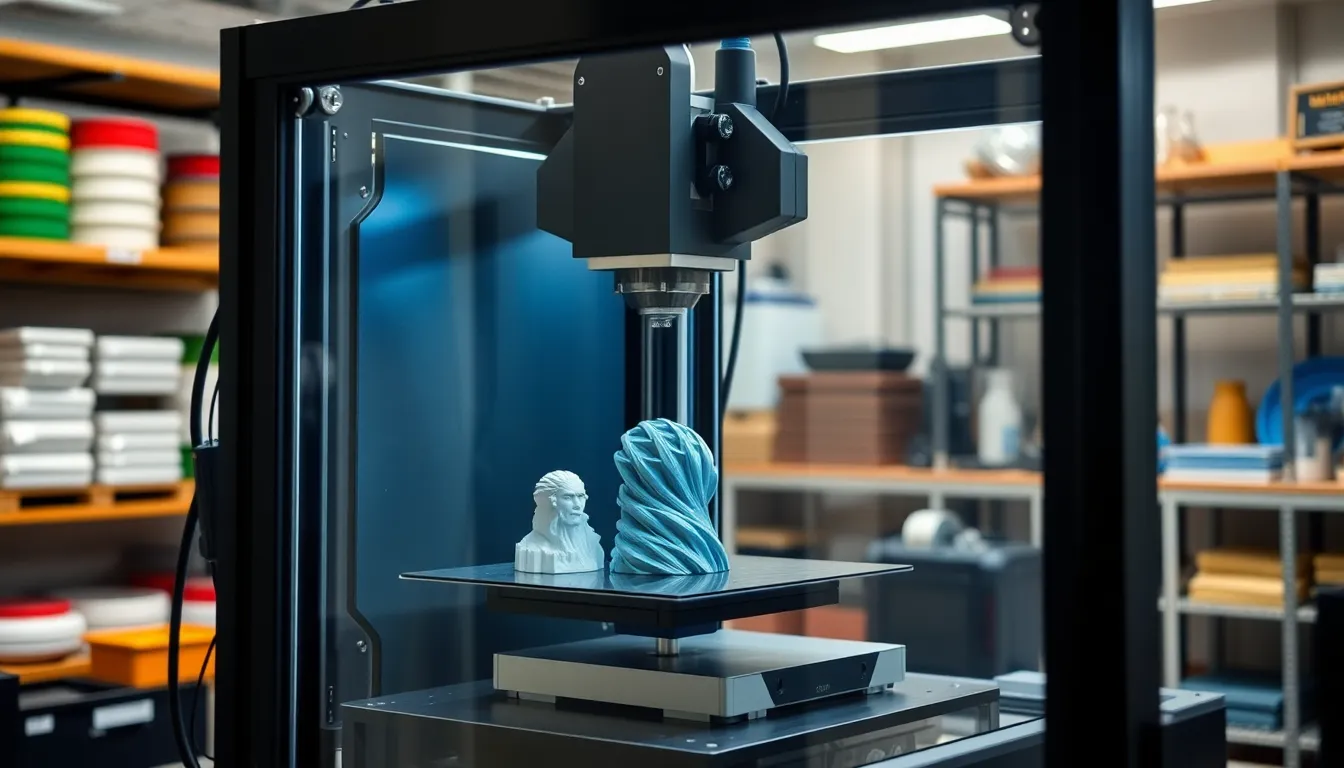

Industrial 3D printing, often known as additive manufacturing, constructs objects layer by layer. This technology enables the production of complex geometries that traditional manufacturing methods struggle to achieve. Various sectors, such as aerospace, automotive, and healthcare, utilize 3D printing for rapid prototyping, customization, and efficient production processes.

Many materials integrate into industrial 3D printing, including metals, plastics, and ceramics. Each material allows manufacturers to select the best option for specific applications. The flexibility in material choice enhances design possibilities, leading to innovative products.

Reduction in waste marks another significant advantage of 3D printing. With traditional manufacturing, excess material often becomes scrap. In contrast, additive manufacturing uses only the necessary material for production, resulting in a more sustainable approach.

Cost-effectiveness becomes apparent when considering small production runs. Traditional methods may require expensive molds and tooling, while 3D printing eliminates these upfront costs. Companies benefit from lower startup expenses and reduced time-to-market for new products.

Speed plays a crucial role in today’s competitive landscape. Industrial 3D printing allows rapid iterations of designs, enabling quicker adjustments based on testing or feedback. This agility gives businesses a vital edge over competitors.

Integration of 3D printing into supply chains has revolutionized logistics. Parts can be produced on-demand, minimizing inventory costs and storage requirements. Organizations are better equipped to respond to market demands with this increased efficiency.

Industries are embracing industrial 3D printing as a powerful solution for modern manufacturing challenges. The technology continues to evolve, offering opportunities for innovation and improved production methods.

Key Technologies in Industrial 3D Printing

Industrial 3D printing employs various advanced technologies that enhance production capabilities and efficiency. Two prominent methods are Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS).

Fused Deposition Modeling (FDM)

Fused Deposition Modeling remains one of the most prevalent 3D printing techniques in industrial applications. In this process, thermoplastic materials are extruded through a heated nozzle, building parts layer by layer. This method offers significant advantages in terms of cost and simplicity, making it accessible for rapid prototyping. Many industries utilize FDM due to its ability to print durable and complex designs. Options include a wide variety of thermoplastics, enabling customization of material properties based on application needs. FDM technology allows for quick iterations in the design process, facilitating faster time to market for new products.

Selective Laser Sintering (SLS)

Selective Laser Sintering utilizes a high-powered laser to fuse powdered materials, creating solid structures. This technology excels in producing highly complex geometries that traditional methods often struggle with. SLS supports various materials, such as nylon and metal composites, which enhances application flexibility across industries like aerospace and automotive. The process involves layering powder and selectively melting it, minimizing waste and maximizing design possibilities. SLS is particularly effective for creating functional prototypes and end-use parts, providing strength and precision in finished products. Furthermore, it allows for batch production without the need for specific tooling, thus reducing lead times significantly.

Applications of Industrial 3D Printing

Industrial 3D printing plays a crucial role across various sectors, driving efficiency and innovation. Its capability to produce complex, customized parts serves different industries effectively.

Aerospace Industry

The aerospace industry benefits significantly from industrial 3D printing. Companies often utilize this technology for creating lightweight components that enhance fuel efficiency. Reduction in weight translates directly into lower operational costs for airlines. Engineers frequently employ 3D printing for rapid prototyping, speeding up the design validation process. Production of intricate parts, such as brackets and airframes, becomes feasible using metals and composites. It’s not uncommon for aerospace firms to achieve lower production times and minimize waste through additive manufacturing techniques.

Automotive Sector

In the automotive sector, industrial 3D printing transforms traditional manufacturing processes. Automakers take advantage of rapid prototyping to test designs quickly, reducing time to market. Customization of parts becomes practical, allowing for unique consumer preferences and performance enhancements. Firms often produce tools and fixtures using 3D printing, streamlining assembly lines and ensuring precision. Significant savings on production costs occur due to lower material waste and shorter supply chains. Several manufacturers adopt this technology to facilitate on-demand production and maintain competitiveness in a fast-paced market.

Advantages of Industrial 3D Printing

Industrial 3D printing offers notable advantages that enhance manufacturing processes. Cost-effectiveness serves as a significant benefit, especially for small production runs. Businesses save on materials and manufacturing expenses, maximizing resource utilization.

Speed in design iterations allows companies to adapt quickly. Rapid prototyping facilitates testing and feedback, leading to improved product outcomes. Changes in design can occur quickly, reducing time to market significantly.

Waste reduction enhances sustainability practices. Traditional manufacturing often results in excess materials, while 3D printing minimizes waste by constructing parts layer by layer. This efficiency aligns with environmental goals and allows for responsible production.

Customization capabilities stand out in various sectors. Industries like aerospace and automotive particularly value the ability to create tailored components that meet specific requirements. Clients appreciate the unique solutions that 3D printing provides to address market demands.

Access to complex geometries further distinguishes industrial 3D printing. Traditional methods often limit design possibilities, whereas additive manufacturing enables intricate shapes that were previously unattainable. This factor opens doors to innovative product designs and functional prototypes.

On-demand production transforms supply chain management. Companies can produce items as needed, reducing inventory costs. An enhanced response to changing market conditions strengthens competitiveness.

Improved logistics also features prominently in 3D printing advantages. The ability to manufacture parts closer to the end-user streamlines distribution. This shift lowers transportation expenses and increases efficiency across supply chains.

Overall, industrial 3D printing represents a key asset for various industries, driving innovation and efficiency while supporting unique designs and sustainable practices.

Challenges and Limitations

Industrial 3D printing faces several challenges and limitations that impact its broader adoption. Quality consistency remains a primary concern. Variations in print conditions can lead to defects and inconsistencies in produced parts. These variations affect the integrity and reliability of components used in critical applications, especially in aerospace and automotive sectors.

Material limitations also pose significant barriers. While numerous materials are available, not all are suitable for every application. Each material has unique properties that limit its usability in specific environments or conditions. Furthermore, the mechanical properties derived from additive manufacturing may not always match those from traditionally manufactured parts.

Production speed and scalability present additional hurdles. Although industrial 3D printing facilitates rapid prototyping, scaling production for larger batches may introduce time constraints. Achieving efficiency in mass production often requires supplementary processes, which can offset some of the speed advantages.

Cost considerations influence decision-making for many businesses. Initial investment in 3D printing technology and materials can appear high, particularly for small companies. Long-term savings from reduced material waste and on-demand production may tempt some organizations, but financial feasibility remains a significant factor.

Regulatory compliance complicates integration into traditional manufacturing. Industries, especially those in aerospace and healthcare, must meet stringent standards for safety and reliability. Navigating these regulations can slow down the adoption of 3D printed components as companies adjust processes to ensure compliance.

Finally, the skill gap in the workforce limits advancements. Many companies struggle to find experts knowledgeable in additive manufacturing techniques. As the technology evolves, continuous training and education become essential to maximizing its potential.

Industrial 3D printing is reshaping the landscape of manufacturing with its unique capabilities and advantages. As industries embrace this technology, they’re discovering new ways to optimize production processes and enhance product design. The ability to create complex geometries and customize parts on demand offers businesses a significant edge in today’s competitive market.

While challenges remain, such as quality consistency and material limitations, the ongoing evolution of 3D printing technology promises to address these issues over time. As more companies invest in training and innovation, the potential for industrial 3D printing to drive efficiency and sustainability continues to grow. This transformative force is set to redefine how products are designed, produced, and delivered across various sectors.