Table of Contents

ToggleIn the world of 3D printing, the raft is like the unsung hero of the printing process. It’s that trusty sidekick that swoops in to save the day, ensuring prints stick to the build plate and don’t go rogue halfway through. Imagine trying to bake a cake without a pan—chaos, right? That’s what a 3D print without a raft feels like.

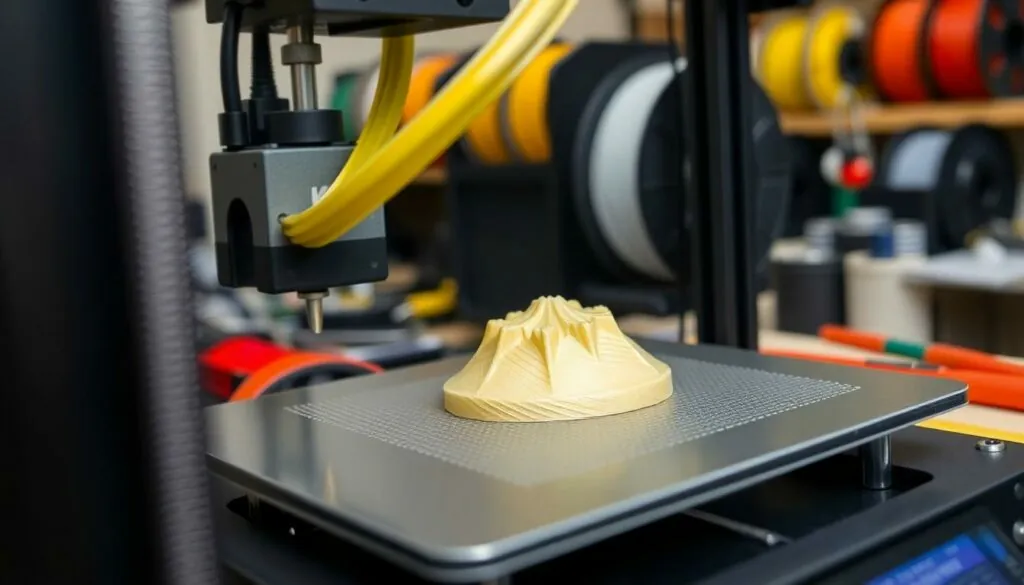

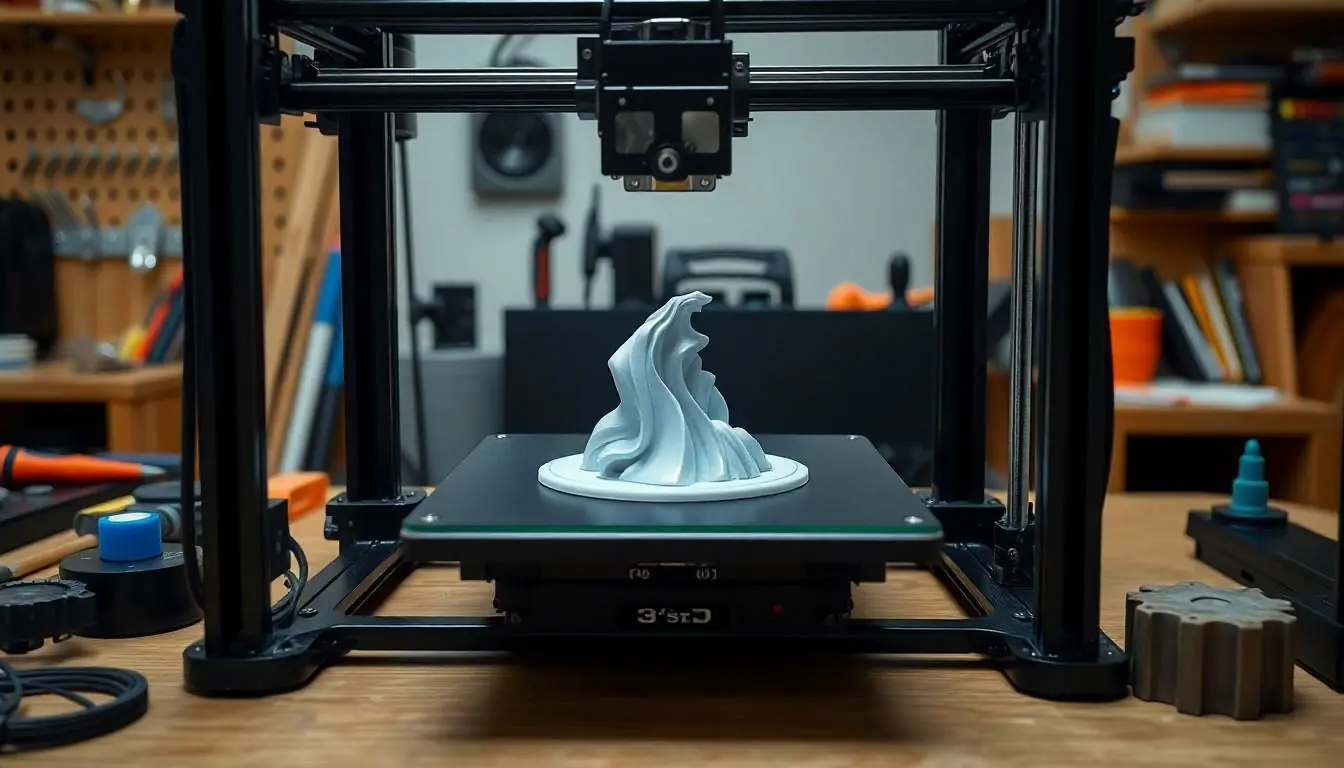

Overview of 3D Printing Rafts

3D printing rafts play a crucial role in ensuring successful prints. They provide a stable foundation that aids in adhesion to the build plate and enhances print quality.

What Is a 3D Printing Raft?

A 3D printing raft consists of additional layers of material created beneath an object during the printing process. These layers sit between the print and the build plate. They support the primary model, reducing the chances of warping or detachment during printing. Typically, rafts are made from the same filament as the model. Some printers generate rafts automatically based on user settings or design requirements.

Importance of Rafts in 3D Printing

Rafts improve print adhesion and stability, especially for models with small base areas. They act as a barrier against uneven build plate surfaces, mitigating risks of print failures. Additionally, rafts facilitate easier removal of prints after completion, preventing damage to the model itself. In cases of complex geometry or intricate designs, rafts even out temperature changes during printing. This reduces the potential for warping, ensuring higher precision and quality in the final product.

Advantages of Using Rafts

3D printing rafts offer several notable advantages that positively impact print outcomes. These benefits include improved adhesion and enhanced print stability.

Improved Adhesion

Rafts create a larger surface area for models, which is crucial for effective adhesion to the build plate. Models with small base areas face higher risks of detachment during the printing process. Using a raft significantly reduces this risk by providing a secure foundation. Additionally, rafts counteract potential warping that can occur with certain materials. This stability during the initial layers leads to a stronger bond between the print and the plate. Furthermore, using a raft helps in achieving better results with intricate designs and complex geometries.

Enhanced Print Stability

Stability during the printing process directly affects overall print quality. Rafts contribute to maintaining consistent contact with the build plate, which keeps models firmly in place. Uneven build plate surfaces often lead to complications, but a raft acts as a buffer against these inconsistencies. By absorbing minor fluctuations, rafts ensure that prints remain accurately positioned throughout the build. This enhanced stability is particularly beneficial for tall or narrow structures. Consequently, users experience fewer print failures and higher success rates with their 3D projects.

Disadvantages of Using Rafts

Using a raft in 3D printing presents certain drawbacks that can affect the overall printing experience.

Increased Material Usage

Increased material usage poses a significant disadvantage of using rafts. Rafts require the addition of extra filament beneath the primary object, leading to higher consumption of material. This added layer can substantially impact costs, especially for large projects that demand extensive filament. Excess material not only increases expenses but also contributes to waste, which can be detrimental to sustainability efforts. Reducing the filament needed for rafts remains challenging, and while some users may find rafts beneficial, many experience material efficiency concerns when printing with rafts.

Post-Processing Challenges

Post-processing challenges may arise when models contain rafts. Removing rafts can prove difficult, requiring additional time and effort to separate them from the finished object. Depending on the model’s geometry, stubborn rafts may leave behind unsightly marks or imperfections on the print’s surface, affecting overall aesthetics. Users might need to invest extra resources in sanding or trimming to achieve the desired finish. Additionally, intricate designs may complicate raft removal, as filaments can bond strongly with the primary model, leading to frustration. Balancing the pros and cons of using rafts hinges on successfully navigating these post-processing hurdles.

Best Practices for Implementing Rafts

Implementing rafts in 3D printing requires careful consideration of settings and material choices. By following best practices, users enhance the overall printing experience.

Settings and Configurations

Optimizing settings significantly impacts raft performance. Adjust layer height for the raft to achieve a tighter bond with the build plate; a lower height promotes better adhesion. Increase the raft surface area in the slicing software to provide additional stability for models with small bases. He must also experiment with raft thickness; thicker rafts improve adhesion but use more material. Setting a slower print speed can reduce issues like warping, leading to more consistent layers. Ensure the nozzle temperature aligns with the filament; accurate temperatures optimize adhesion and reduce the risk of detachment.

Material Considerations

Choosing the right material is crucial for successful raft implementation. PLA offers excellent adhesion and is a user-friendly choice for beginners. Selecting ABS can provide more durability and strength but may require additional cooling strategies. Advanced users might consider using specialized filament that enhances adhesion and improves thermal stability. Always ensure the filament diameter matches the printer’s specifications to avoid feed issues. Test different materials for effectiveness; some may bond more tightly to the raft, reducing post-processing challenges.

Utilizing a 3D printing raft can significantly enhance the quality and success rate of prints. By providing a stable foundation and improving adhesion, it minimizes the risk of warping and detachment. While there are some drawbacks like increased material usage and potential post-processing challenges, the benefits often outweigh these concerns.

Careful consideration of settings and materials can further optimize raft performance. For those looking to achieve precise and reliable prints, incorporating a raft into the 3D printing process is a wise choice. Ultimately, understanding how to effectively use rafts can lead to more successful and satisfying 3D printing experiences.